What is terracotta?

A building’s façade can feature an array of materials such as timber, masonry, fibre cement, metal, steel and aluminium. The design and performance characteristics of these materials vary significantly, and your choice of cladding should be based on a careful assessment of the project’s climate conditions, as well as the aesthetic design intent.

As a building product, terracotta has been in use for thousands of years however of late, terracotta has gained increasing interest from architects and designers looking for a compliant and durable material that adds texture, warmth and character with beautiful, rich and earthy-tone colours.

Terracotta cladding is made from clay ground to a fine dust, mixed with water, extruded to shape, then fired at incredibly high temperatures in order to create an architectural cladding material that offers resistance to extreme weather, thermal insulation, a natural texture and is recyclable.

“Fairview’s Clayton terracotta ventilated façade system is ideal for large scale landmark constructions,

designed to leave a green footprint with character for our future communities”,

Meena Somi, Fairview’s Senior Category Manager

Terracotta – Achieve an eco-friendly design that makes an impact with its exquisite beauty.

Aesthetics

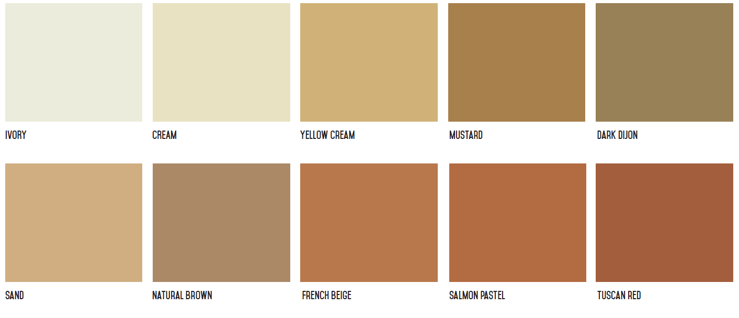

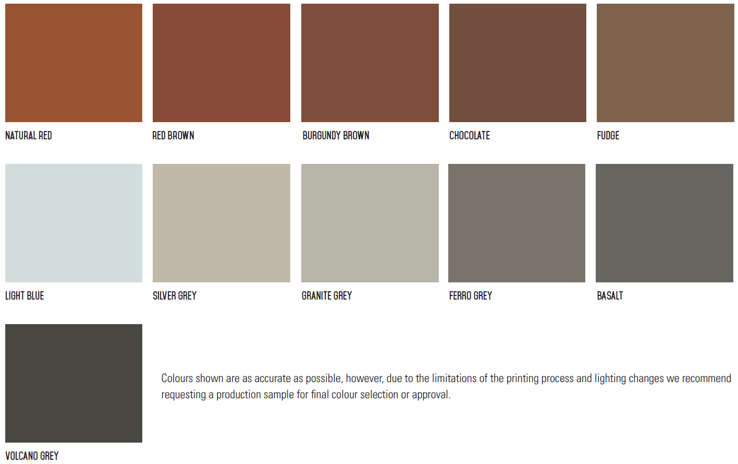

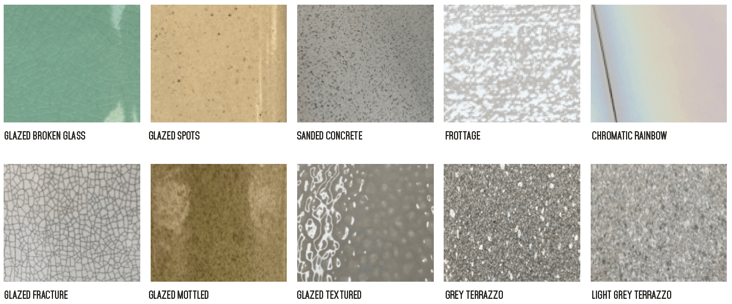

The range of colours that can be achieved with terracotta cladding is endless. Terracotta is well known for its red earthy colour, however, the options for colours range from beautiful earthy browns to neutral beiges and greys. The colour finishes for terracotta generally fall into two categories - glazed and unglazed.

Glazed: Glazed terracotta starts with a body colour, normally white or off-white, a glaze is then applied to the surface prior to the firing process, giving you the ability to achieve different opacities and finishes. The glaze can be transparent allowing you to see the body colour underneath or be completely opaque.

The glazing process also provides an opportunity to add gloss, giving you the ability to create finishes that range from matte, all the way to high gloss. During the production process, it’s also possible to combine two or three glazes on different layers to create other special effects including a process called digital engobing. Like digital printing, digital engobing involves applying a digital image on top of an engobed clay panel, in the firing process, the applied image fuses with the engobe and the panel to form an inseparable unit - allowing you to create patterns such as the one’s below:

Unglazed: Various cladding colours can be created by mixing different types of clay. Natural terracotta colours normally include ivory, cream, and grey, as well as a range of brown hues. In order to increase the range of colours on offer, pigments or oxides are added to the clay to give you an almost endless range of options to choose from.

Careful development work is involved in creating new colours as in most cases the final colour is a function of the clay, pigment, oxides and the heat applied during the firing process. The tile colour going into the firing process can be very different to the colour that emerges from the firing process.

This process of creating the colour and vitrification of the colour into the clay creates stable and ever-lasting colours that will easily endure over 50 or more years.

Clayton offers a range of 21 standard and 10 specialised colours in the range.

Terracotta Panel Profiles and Textures

Terracotta panels are renowned for adding warmth and texture to any architectural design. Within the Clayton terracotta cladding range, there are numerous contemporary, classic and specialised profiles and baguettes, with unique surface textures and grooves, adding to the flexibility in design and the imagination of the architect.

Terracotta Baguette Shapes

Not only do terracotta baguettes add colour, depth and form to any building they also act as a sun shade or screen reducing the amount of radiant heat reaching the building.

Clayton's range of 7 distinct terracotta baguettes will give a beneficial and modern appearance to designs.

Combining 11 terracotta panel profiles with various textured surfaces, 7 terracotta baguettes with unique shapes, and an extensive range of terracotta colours allows for endless possibilities for the design aesthetics of the building. Terracotta not only offers improved performance as a cladding product but also removes design constraints associated with other cladding products – making it the ideal option for contemporary buildings.

Traditionally, terracotta cladding used to be flat – however, with improvements in production technologies the options for profiles and specially shaped terracotta cladding have grown, offering shadow effects and a three-dimensional appearance to designs.

Historically – buildings in Australia have tended to rely heavily on metal cladding of various forms – there is a strong trend towards alternative cladding products that bring warmth, texture, dimensional variety and a shift towards natural and Earthy products.

There is still a lot of unexplored potential in using terracotta as a cladding material on buildings. The Clayton range of terracotta cladding is the right product for architects looking to challenge the status quo and reinvent buildings with a traditional building material that offers features that cannot be matched with typical building products.

With its excellent thermal and cooling efficiency, improvement of sound protection, non-combustibility and frost-proofing, Clayton is not just a decorative cladding material, but a product that enhances the sustainability of the entire building.

Explore the sustainable, efficiency and performance benefits of the Clayton terracotta rainscreen system at Clayton Terracotta Cladding.