Oil canning is defined as the perceived waviness of a metal panel and is an inherent characteristic of light-gauge, cold-rolled flat metal products. It’s a visual phenomenon that makes metal panels look wavy or somewhat distorted, especially in the broad, flat areas of a metal wall system.

Oil canning is simply a cosmetic effect and does not affect the structural integrity of the panel system, nor does it discriminate between the different metal types and can occur with any type of metal material used in construction.

Oil-canning is not a new occurrence and has long been a part of architecture history, dating back to medieval times where application of natural metals such as zinc and copper for roofing meant that oil-canning was a common feature of the architectural landscape. As materials have advanced and aesthetic preferences changed, buildings have been designed and engineered to achieve a cleaner and streamlined look.

Whilst there are still some within the architectural space who prefer the authentic look of natural metals, many are actively seeking to specify products that will maintain their clean-line aesthetic integrity.

As part of Fairview’s commitment to product performance, improvements and innovation, a study was conducted to determine the resistance of Vitracore G2 against forces that would create oil canning.

Fairview’s Vitracore G2 is a bonded aluminium panel, with a non-combustible profiled aluminium core, engineered for high performance and unmatched by other metal cladding products.

The analysis was conducted by an external engineer and featured the use of Finite Element Analysis (FEA) software to determine the performance of both G2 and 3mm solid aluminium against oil canning.

In understanding the benchmarks against which the study was conducted, first it is important to detail the known causes and ways to minimize the chance for oil canning, which include:

- Stresses during the production process:

Oil canning can sometimes occur during the early stages of the coiling production. There are three separate stresses that can be induced on the metal during production that could lead to the development of oil canning:

- Full centre: The coil is longer in the middle section, which creates ripples or buckles along the centre.

- Wavy edge: The edge of the coil is longer along the edge of the strip.

- Camber: The coil deviates from a straight line when laid flat (similar to the curvature of a banana)

- Stresses during roll forming and slitting:

All metals have a “memory” which sees the material displaying a tendency of “trying” to revert back to its original form. The stresses inflicted during roll forming and slitting of the metal coil and sheets can facilitate oil canning as the metal moves and warps in response to metal “memory”.

- Incorrect fastener installation:

There are two common scenarios where oil canning could be attributed to fasteners:

- Over-driving fasteners: The over-tightening of fasteners can cause stress to the metal as it deforms due to the pressures of the fastener on the surface of the metal.

- Angling fasteners: Driving the fastener at an angle when attaching the panel to the wall can create stress that could lead to oil canning.

- Inadequate space allotted for thermal movement:

Metals expand and contract with heat; therefore restricting the expansion and contraction needed for proper thermal movement of a metal panel can lead to oil canning. This commonly occurs when panels are double pinned at the edges, which restricts the centres from moving during thermal expansion/contraction and causes stress on the metal.

- Structural changes that put tension on the panels:

Oil canning can also occur when the building experiences a shift in its structure, settles in its foundations, or experiences a force that results in a change in the building envelope from its original form.

The movement in the building needs to be sufficient to induce tension or stress on the metal panels. This influence on oil canning is infrequent but possible if the building is subjected to extreme weathering that can affect the building structure.

- Out of plane/square building structure.

Careful attention should be paid to ensure the substrate that the façade is being installed on is as close to flat and square as possible. Even small values of out of square can lead problems as most façade cladding spans lengths of up to 4 mt. The longer the span the greater the impact of any out of square on oil canning.

Being a bonded laminate comprising of a profiled aluminium core with an aluminium skin on either side, Fairview’s Vitracore G2 offers the best of both worlds. Being half the weight and 50% more rigid compared to the solid aluminium options in the market, Vitracore offers improved performance against the forces that can lead to oil canning.

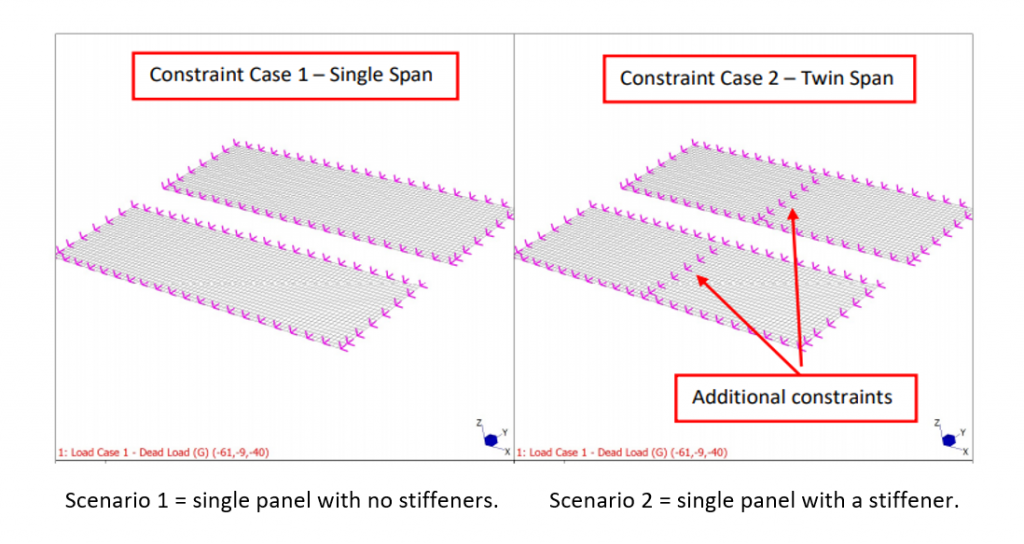

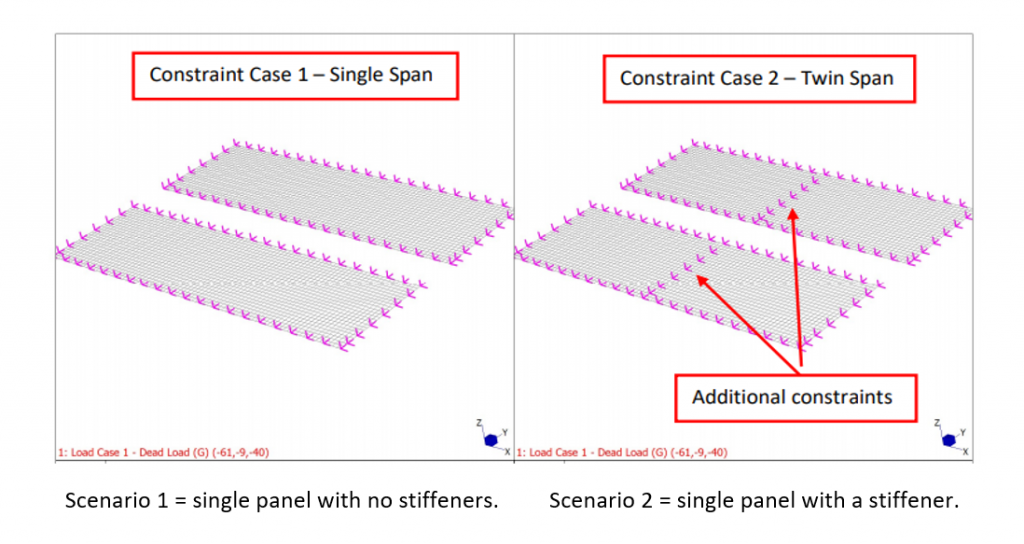

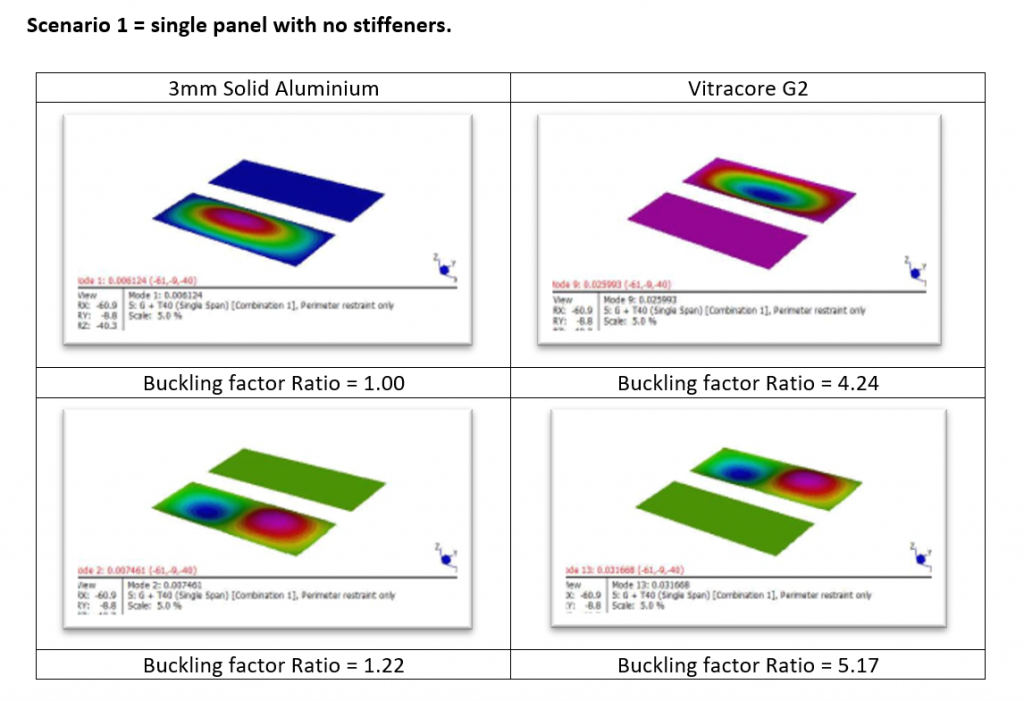

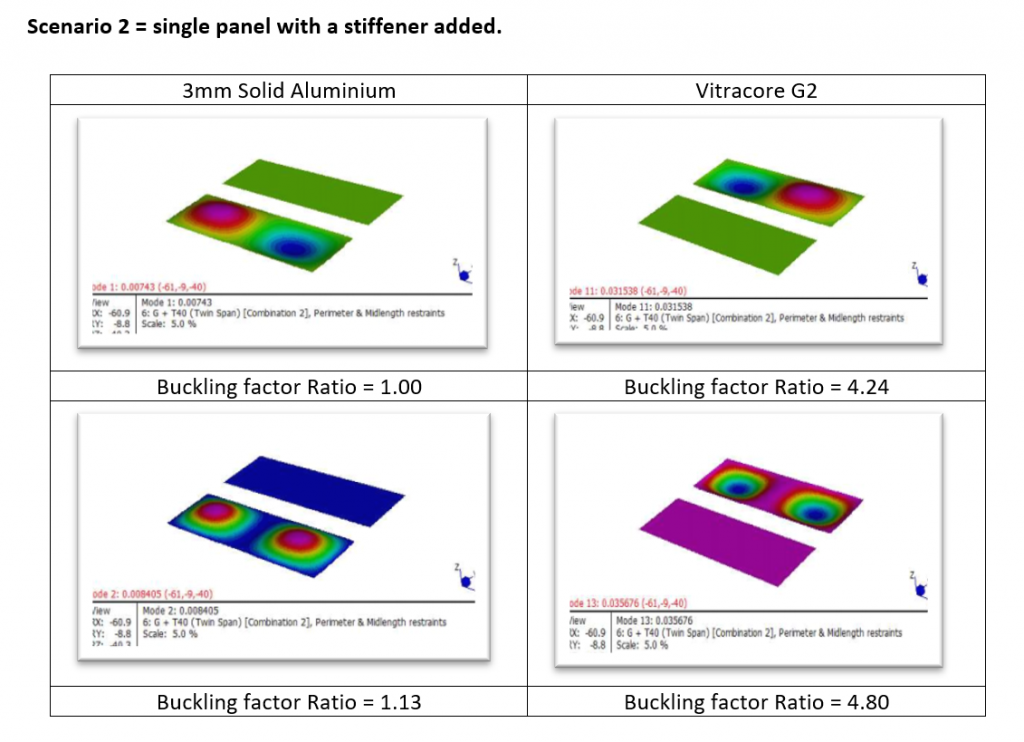

Using FEA analysis, two scenarios were analysed:

Using the FEA software to add a buckling load that would simulate a load that would bring about an oil canning effect on either panel (referred to as Buckling Factor Ratio). The results being:

In this Scenario – Vitracore panel is at a load more than 4 times greater than the buckling mode for the 3mm aluminium panel.

In this scenario - the Vitracore panel is again more than 4 times greater than the buckling mode for the 3mm aluminium panel. Adding stiffeners did not change the result.

Conclusion:

This analysis demonstrated the superior performance of Vitracore G2 and specifically

- The 3mm solid aluminium panel is significantly more susceptible to thermally induced out of plane buckling.

- The frequency of support spacings less than 200mm did not appear to significantly alter the results.

- Vitracore G2 panel would in have around 70% greater buckling resistance.

In addition to Vitracore G2’s superior performance, the product provides many benefits, making it the decisive solution to high demand and industry requirements.

The lightweight nature of the panel design aids in installation procedure and efficacy, reducing overall construction cost, the almost limitless range of colours and finishes, including the option of customisable graphic panels makes it easy to achieve design intent, and finally G2’s comprehensive compliance verification documentation is unmatched by any cladding material in Australia.