Earlier this month Fairview hosted the Sustainability in the Design & Construction Industry. The webinar was well received and there was a lot of great information we would like to share with you from this event.

Please find below a recap of the presentations from the sessions.

Sustainability Trends in the Design & Construction Industry

Professor Vivian Tam, Western Sydney University

Sustainability in the construction industry can be considered from three dimensions of planet, people, and profit across the entire construction supply chain. Key concepts include the protection of the natural environment, choice of non-toxic materials, reduction and reuse of resources, waste minimization, and the use of life-cycle analysis.

Trends in the construction industry include:

The construction industry is a major consumer of natural resources & global aggregate production almost double from 21 billion tons in 2007 to 40 million tons in 2014. There is a high potential for recycling and reuse of C & D waste. The level of recycling and material recovery through varies greatly between countries.

There are four potential options for C & D recycling waste

- Prevention: informed about new ways to design materials by keeping in to account their disposal and recycling and their environmental impact.

- Separation: encouraged recycling and deterring disposal in landfill

- Treatment: it proposed the introduction of a system based on permissions and licenses issued to those businesses involved in the production of C&D waste. The qualified contractor must indicate the produced waste amount, the adopted measure for treating it and its final destination.

- Market: the market for C&D waste could develop if the suburban public administrations exercise a model role as a purchaser.

Our built environment is currently the world's single largest contributor to greenhouse gas emissions, it consumes around a third of our water, and generates 40 per cent of our waste.

Green Building Council of Australia - Green Star Program

Dr Mark Jackson, Director, Jackson Environment and Planning Pty Ltd

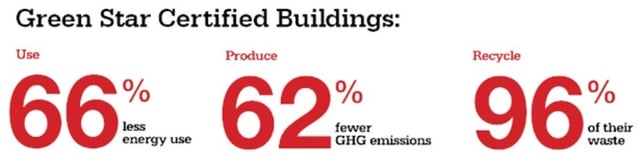

Launched by Green Building Council of Australia (GBCA) in 2003, Green Star is Australia's largest voluntary and truly holistic sustainability rating system for buildings, fitouts, and communities.

Green Star aims to transform the built environment by:

- reducing the impact of climate change

- enhancing our health & quality of life

- restoring and protecting our planet’s biodiversity and ecosystems

- driving resilient outcomes for buildings, fitouts, and communities

- contributing to market transformation and a sustainable economy

The key drivers of Green Star in the building industry are:

- lower operating costs

- higher return on investment

- attract and retain tenants

- enhanced marketability

- productivity benefits

- reduced liability and risk

- healthier places to live and work

- demonstration of Corporate Social Responsibility

- future-proofed assets

- competitive advantage

It is important to note that Green Star also allocated points for the management of construction waste and aims to reward construction practices that minimise demolition and construction waste and landfill contribution.

Rethink Rectification and Cladding Waste - Ecoloop, ACP Recycling Solution

Melissa Herrmann, Industry Engagement Management & Gary Norris, National Facade Manager - Rectification & Recycling, Fairview

Through collaboration with industry experts EcoSmart, extensive research and several trials Ecoloop, ACP Recycling Solution was developed.

With the only current offerings for cladding rectification waste been landfill export going to developing nations there wasn’t a sustainable or ethical solution here in Australia.

Ecoloops commitment to sustainability is 100% Australian, 100% diversion from landfill and 100% repurposed products.

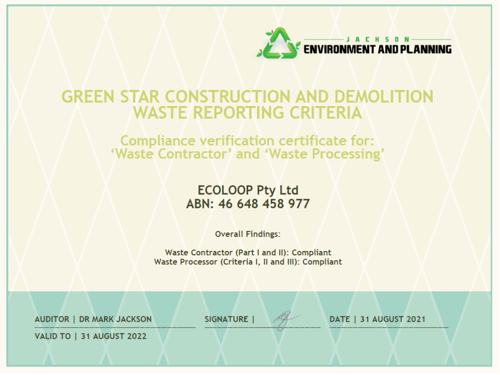

Ecoloop, has been verified by to comply with Green Building Council of Australia’s (GBCA) Construction and Demolition Waste Reporting Criteria.

The GBCA’s Construction and Demolition Waste Reporting Criteria allows waste contractors and waste processing facilities to be verified by an independent auditor for compliance with minimum standards of reporting. This is a critical step in ensuring not only transparency in the industry but also customer confidence regarding the recycling of waste.

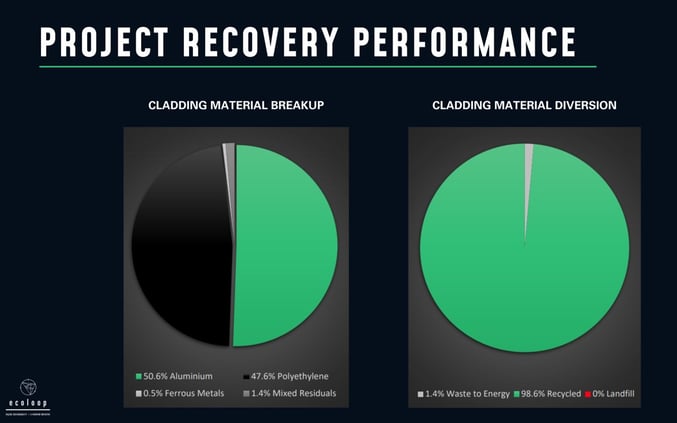

Since it began Ecoloop has assisted may rectification projects with managing their waste. The Blackman Hotel Refurbishment Project in Victoria is one we would like to share a case study with you.

- 1400 sqm of PE Core waste panels were collected for Ecoloop recycling.

Please see below a snapshot of the breakdown of the panels that were processed through the ecoloop facility.

LiteCorp - Sustainable building and packaging materials

LiteCorp - Sustainable building and packaging materials

Matthew Dorhauer, Lite Corp

LiteCorp has been manufacturing innovative honeycomb cardboard products locally in Australia since 2015.

The range includes Envirocore, Clayform and LitePack/Lite Pallets.

Envirocore

High-quality product that is coupled with print grade Kraft or white facing to provide beautiful environmentally responsible substrates for the printing industry.

The Key Benefits are:

- Stunning print quality

- Available in Kraft or white facing

- Standard sheet size 2400 x 1200

- Thickness of 10/15/20/30 mm

- Easily machinable

- Fully recyclable

Clayform

Lite group clayform is the premier void forming solution for engineers and builders across Australia.

Developed to create space between the soil and building foundation, Clayform reduces the upward force transmitted to the structure due to ground heave. Clayform has the ability to support the load of concrete when it is poured and due to its degradability will break down over time leaving a genuine void. This reduces the risk of reactive soils impacting upon the slab or causing damage to the structure in the future.

Lite Pack / Lite Pallets

Our Lite Pallets are the robust, eco-friendly, and cost-effective option for one-way delivery and display of your stock and inventory. The strength of Lite Pallets lies in the design of the honeycomb core and sandwich layers, which mimic the steel I-beam that is often used in load-bearing applications in construction. Unlike steel, honeycomb cardboard pallets are made from easily recyclable, light paper. They can handle considerable loads without adding any significant weight to shipment. These are the perfect solutions for one way and B2C deliveries using environmentally responsible materials at an economical price.

Key Benefits

- Environmentally responsible

- Reduced labour costs

- No ISPM15 requirements

- One-way B2B and B2C Deliveries

If you would like more information about Sustainability in the Design & Construction Industry please don't hesitate to contact a member of our friendly team.

-2.jpg?width=500&name=20_Shepherd_st_Liverpool_0088%201%20(1)-2.jpg)