In achieving a high performing façade with Vitracore G2, adequate quality controls as well as leading edge production facilities are critical to success.

The production facilities that manufacture Vitracore G2,

- source A-grade aluminium,

- audits incoming raw materials to actively seek, isolate and eliminate defects in raw materials,

- has developed standardised and repeatable production processes,

- ensures staff are appropriately trained,

- employs a Quality Assurance function that is accountable to senior management,

- as well as conducting checks of production stock at regular intervals.

The factory used to produce the Vitracore G2 is also independently assessed and audited by CodeMark to ensure the systems Fairview and its manufacturers have in place are adequately geared to produce a quality product.

Fairview’s Vitracore G2 has been engineered to offer the highest in performance in areas including flatness, resistance to out of plane buckling, rigidity, resistance to compressive loads, lamination strength and weight advantage over other façade products.

These advantages are thanks to the core of the G2 – made from a profiles 3mm core, expanded to 2.8mm and working together with the skins like a honeycomb structure to increase strength while keeping the weight down.

To create this high-performance façade, an advanced manufacturing process is used to create each component in the make-up of the G2, then combine the four elements in a banded laminate structure that enables the G2 to offer a high performing façade solution that meets and exceeds all Australian building requirements.

What makes up Vitracore G2?

Components of Vitracore G2 include:

Manufacturing Vitracore G2 is a careful engineering process to assemble the components of the G2 into a bonded laminate façade that yields outstanding performance.

Manufacturing Process

Vitracore G2 is manufactured using a continuous lamination process where the three aluminium layers (face skin, profiled core, and rear skin) are bonded together into a complete panel. This enables a precise and durable façade product. The rigidity of Vitracore G2 alleviates oil canning and panel deflection, proving it to be an exceptionally durable façade product for decades to come.

The stages of manufacturing include:

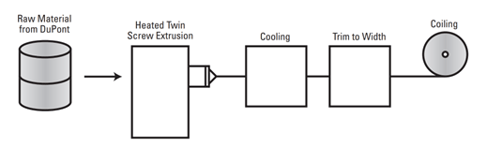

1. Dow Bynel adhesion film:

The adhesive used to bond the three aluminium layers is extruded in a thin film with an overall thickness of 0.04mm. This is cooled, trimmed to width then rolled onto a core ready to be applied.

During the extrusion process, quality control checks are performed to ensure that the film is uniform in consistency and thickness.

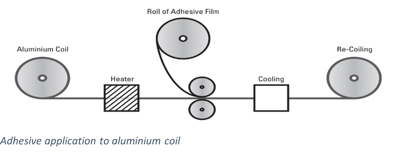

2. Application of Dow Bynel film:

Prior to the manufacture of G2, the film is applied to the surfaces of the three aluminium components. The film is applied to the underside of the face and rear skins as well as both sides of the core.

During the lamination process, heat and pressure is applied to activate the bond. Given the pressure and nature of the profiled core this creates very slight variations in the thickness of the film in the finished panels but does not affect the overall consistency of the adhesive film.

Overall, two layers of Dow Bynel film is used with a total thickness of 0.16mm, which represents 8% of the allowable thickness as stipulated in the National Construction Code.

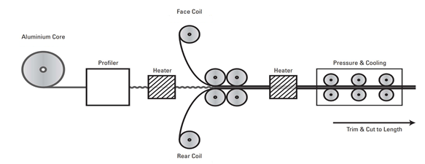

3. Assembly of the G2 panel:

Vitracore G2 is manufactured using a continuous lamination process where the three aluminium layers (face skin, profiled core, and rear skin) are bonded together into a complete panel using a pre-applied Dow Bynel adhesive film (hot melt glue).

- Profiling of the core: The 0.3mm aluminium used on the core of the panel is processed through a profiler and expanded to a 2.8mm profiled core.

- The profiled core then progresses to the lamination stage where the face and rear skin are placed on either side of the profiled core then placed under heat and pressure to activate the bond between the tree components.

- The result is a panel with superior flatness and laminations strength whilst having the lowest adhesive content of any decorative metal cladding apart from solid materials.

Batch Testing

To ensure a quality product, batch testing is conducted with each production of Vitracore G2. Through each production run, at each 200mt of produced stock, a sample is cut for testing to check:

- Colour conformity to a master sample

- Panel gloss level against a master sample

- Peel strength to confirm the strength of the adhesion of the 3 components that make the G2.

- The Peel is carried out at the time of installation, then at the 2-, 4- and 6-week mark post manufacture.

- In between the test intervals, the sample is left outside, exposed to the elements, tested regularly, and cycled through hot and cold.

Below is table shows a sample of the testing that is carried out: Refer to the article titled “Vitracore G2 Core Engineered for Performance” for in–depth information on the testing conducted to engineer a high performing façade solution

Refer to the article titled “Vitracore G2 Core Engineered for Performance” for in–depth information on the testing conducted to engineer a high performing façade solution

Ongoing Quality Control and Testing

360 VIEW is the highly unique, quality control process Fairview developed to govern our rigorous approach to design and sourcing, material testing, regulatory compliance, and product warranty.

Our Total Quality Control process starts and ends with customer satisfaction: your satisfaction governs how we think, act, and deliver from the design shop to the fabrication floor and from customer relations to product sureties.

Vitracore G2’s Independent Testing and Auditing

Vitracore G2 is manufactured in carefully quality controlled and regularly audited factories. This auditing has been undertaken under three separate product and quality control schemes:

- UL (Underwriters Laboratories) – UL have been engaged in ongoing auditing of Fairview manufacturing.

- ISO 9001 – this is an international standard for product quality, provided and audited by an IAF, QMS Certification and CNAS approved body.

- BBA (British Board of Agreement) Approvals – A BBA (British Board of Agreement) Approval is a holistic review of product compliance and manufacturing conducted by the BBA.

- CodeMark – this is an ABCB owned scheme with a JAS-ANZ approved body certifying compliance, requiring audits to be undertaken on both the manufacturing quality and the finished product as supplied to the market.

Fairview guarantees that any Vitracore G2 being supplied to the market is 100% consistent with what has been tested and certified as compliant with the BCA (Building Code of Australia).

Fairview and affiliates have taken and are continuing to take actions to prove the consistency, reliability, and performance of G2. These include (but are not limited to):

- UoW (University of Wollongong) – UoW were engaged in October 2018 to independently secure Vitracore G2 from various building sites and conducted testing to verify the products compliance.

- RED Fire Engineers – reviewing reporting and testing by University of Queensland.

- Other industry experts – have been engaged to assist with product testing, reviewing the testing methods and fire compliance including further testing labs and engineers from different fields.

The result of this production process, coupled to strict testing ensures a quality product free from defects and one that will last for the design life of the building.

No other external façade product has had the same level engineering, testing, and compliance assessment as Fairview’s Vitracore G2.

Vitracore G2 is the perfect engineered solution for any cladding application.

Fairview takes a whole of industry approach, and to that end we maintain a sharp focus on education and resource sharing as the industry continues to steady itself. We engage with a range of experts from fire specialists to technologists and bring that knowledge back to the industry to benefit us all.

If you would like to see a sample and explore Vitracore G2 product and specification information for your next project, you can request them here.