Not only should a building’s façade look good upon installation, it must also stand the test of time and withstand environmental factors for long term performance. Through an analysis of testing carried out in September 2022 by Robert Jeffrey at Pacific Testing, it was concluded that 5052 marine-grade aluminium failed to deliver a meaningful performance advantage over the 3003 grade. Furthermore, on sections where the substrate was mechanically fabricated, 3003 significantly outperformed the 5052. As a trusted supplier of aluminium façade panels, the Fairview team took out an independent comparative test with Allunga Exposure Laboratory for an impartial examination of corrosivity performance of 3000 vs 5000 series aluminium through a 1000hr Salt Spray Test.

As a fabricated cassette, the coating on a solid aluminium panel provides the protection against the elements. The better the coating, the better the panel can withstand its environment. So, How do the two grades perform under accelerated corrosion testing?

Testing was conducted to two different coloured panels in both 3003 and 5052 grade of aluminium. The aim of the test was to determine the performance of the panels under three scenarios:

1) Cut edges:

The test on 3003 and 5052 aluminium samples with a white coating showed very similar results with both grades demonstrated blistering, corrosion and staining on the cut edges.

| 3003 Grade | 5052 Grade |

|

|

However, on the dark grey coated samples, the results resemble the findings at Pacific testing, whereby the 3003 grade showed blistering, corrosion and staining, and the 5052 grade only showed a few traces of blistering. It is worth noting that in a typical install, cut edges are caulked, protected from the elements and not visible on the project.

| 3003 Grade | 5052 Grade |

|

|

Typically, on the exposed edges you would expect 5052 grade to outperform 3003 grade as the 5052 (as an exposed raw edge) offers higher corrosion resistance. However, these results did not demonstrate the benefits commonly expected on the 5052 samples.

2) Scratched surface:

Solid aluminium façade panels are extremely durable and major damage to the face of the panel is unlikely. However, how would the panel perform if it is scratched and exposed to the elements?

In the testing, scribe lines were deliberately applied to the samples to determine how the two different grades would react. The 3003 with a white coating showed minor blistering, corrosion and staining along the scribe lines, whereas the 5052 showed significant blistering, corrosion and staining.

| 3003 Grade | 5052 Grade |

|

|

On the dark grey samples, the 3003 grade showed blistering, corrosion and staining and the 5052 grade showed little or no changes. At best, these results can be summarised as inconclusive and point to differences based on coating/colour composition.

| 3003 Grade | 5052 Grade |

|

|

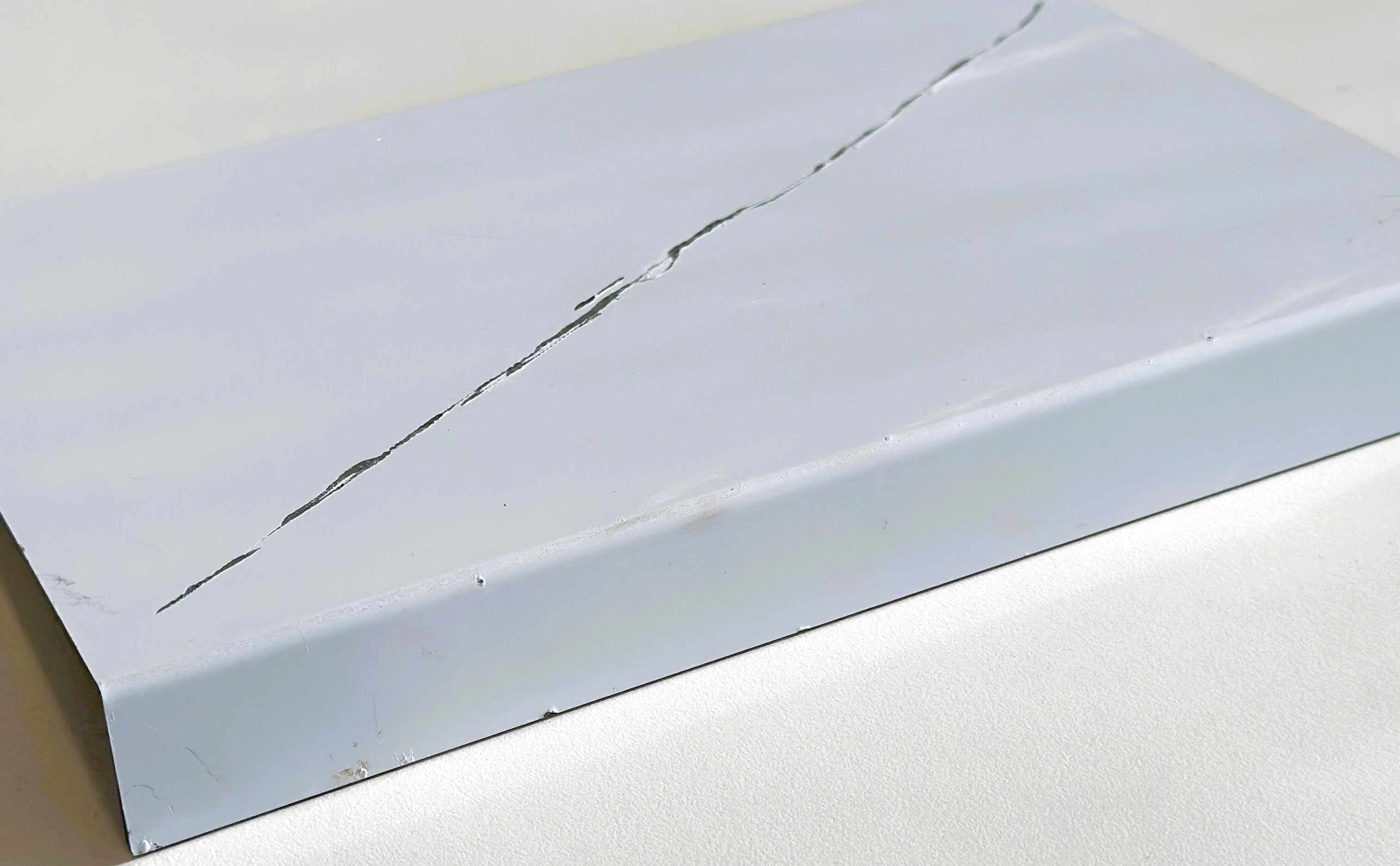

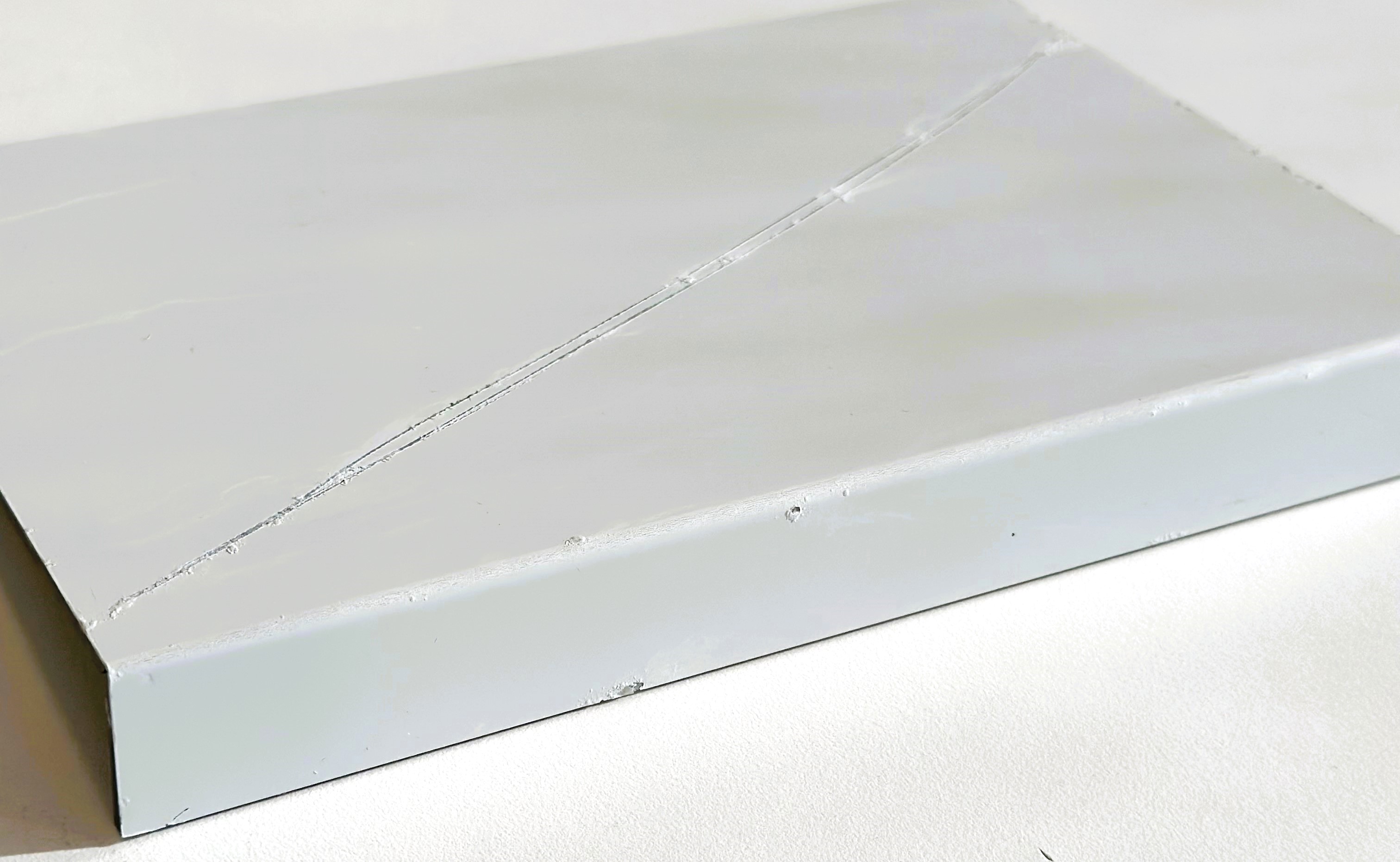

3) Panel Folds:

A major benefit of using solid aluminium for facades is that the panels can be fabricated, curved and rolled. The key question here is – is there a superior grade of aluminium for this particular application? The short answer is, yes. The most impacted part of the panel is the cassette fold, where our testing showed that both the 3003 and 5052 grade yielded a similar level of checking, cracking, blistering and traces of corrosion on the white samples.

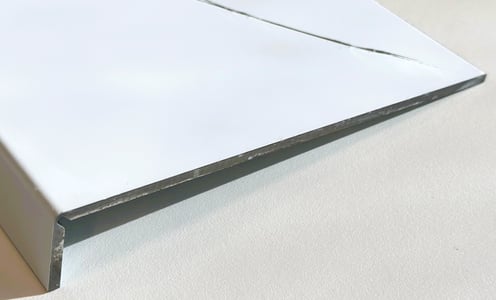

| 3003 Grade | 5052 Grade |

|

|

On the dark grey samples however, our results were consistent with previous findings, where only very fine spots of discolouration occurred on the 3003 grade and no blistering or corrosion was evident. However, on the 5052 grade, areas of blistering, corrosion and staining were evidenced.

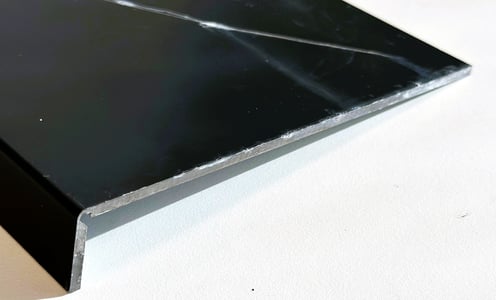

| 3003 Grade | 5052 Grade |

|

|

General market sentiment suggests that 5052 grade aluminium is the superior grade due to its better corrosion performance. However, both inhouse and independent testing offers no evidence that 5052 outperforms the 3003 grade of aluminium in cassette façade applications. In order to maintain the aesthetics of the building, the critical test was the scenario evaluating the panel folds, and it is specifically in this area where the 3003 grade tends to outperform the 5052.

What is the likely cause?

Under normal circumstances, it’s the coating that provides weather protection and forms the first line of defence. When the coating is compromised, we revert to the formation of an oxide layer to protect the aluminium from further degradation. But, it’s the formation of the oxide layer itself that compromises the façade appearance, breaking the coating bond and forming a surface bubble. Within the oxygen deprived bubble, poultice corrosion takes hold and proliferates, while the protective oxide layer is unable to form in the absence of oxygen. It has been widely documented that relative to the more flexible (workable) 3003 grade, the 5052 is prone to micro cracking when bent beyond 90 degrees. Surface cracking in aluminium can break the bond between coating and the substrate, while allowing moisture to penetrate.

Conclusion

It is the coating and material workability properties of 3003 that make it best suited for use in architectural facades. Fabricated panels of coated 5052 have a higher likelihood of being adversely affected by bubbling caused by micro cracking and poultice corrosion.